Believe it or not, 3D printing technologies have actually been around since the 1980’s. Some would say it’s not the awe-inspiring new innovation it once was. Well maybe that’s partially true, it’s certainly not new, but it is undoubtedly awe-inspiring.

Just recently, I found out that MoMA (Museum of Modern Art) New York got their hands on a 3D printed garment. Incredibly, it was then used to create a beautiful dress. Well, being the ready-to-wear fashion enthusiast that I truly am, I was of instantly compelled to attend General Assembly’s ‘Introduction to 3D Printing’ course in February.

So what is 3D Printing?

In techie land, 3D printing is referred as ‘additive manufacturing’. So what does that actually mean? It’s ‘the process of joining materials to make objects from 3D model data’, which means making objects from 3D data layer upon layer. For the rest of us who don’t live in techie land, 3D printing makes a 3 dimensional object.

OK then, how does it work?

Well first you need to create a 3D design file of whatever object you want to make 3D. For that you’ll need a 3D modelling program or scanner. The software then goes about slicing the final model into hundreds if not thousands of horizontal layers. Once you upload it to a 3D printer, it will painstakingly create the object, layer by layer. All very good, but how does a printer create a 3D object? A 3D printer can because set on an XYZ axis. This axis allows the printer’s fuselage to ‘swing’ into different widths, lengths, and heights.

Great in theory but what materials can you actually print in 3D?

You name it, the technology can make it. So far, materials range from plastic through to titanium. Nylon, woods, and bronze are also coming into play. So what does all this 3D printing mean and where is it going? Well let’s use one recent application to perhaps give it some perspective. Late last year, the CSIRO printed a 3D titanium heel. It was used as an implant to replace a Melbourne man’s heel bone. I’ve already told you it can create fashion. And I’m guessing you may have heard about the 3D printed gun. Of course that’s a no-no in Australia and you’ll be up before the court quicker than you can pull the plastic trigger.

The applications are in fact endless. Bathsheba Grossman, an American artist, has been creating sculptures with 3D printing that function not only as art or jewellery, but also housewares. There are even wood chips available now and a group of architects in Amsterdam are building an entire house using a 3D printer.

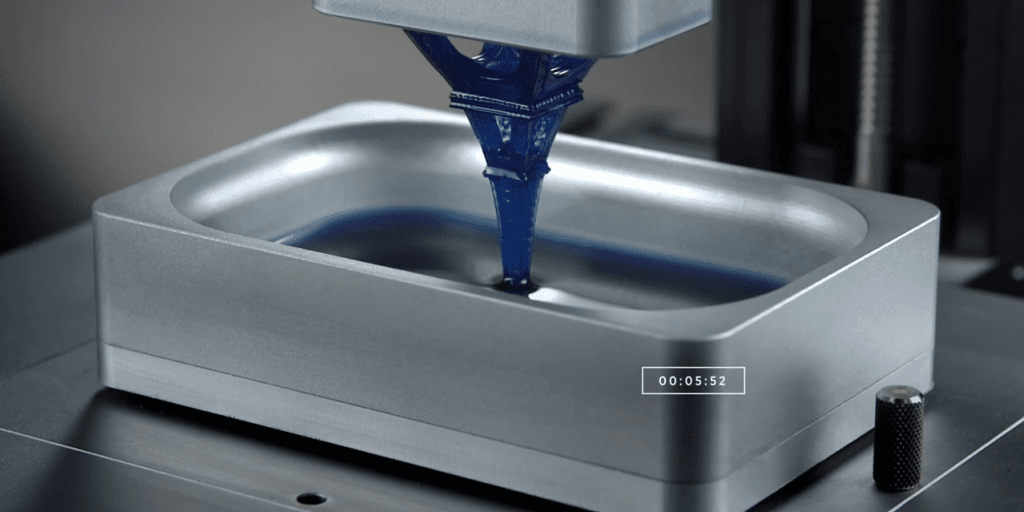

However, the most recent development takes 3D printing to another level and changes the game again. An entirely new process involves a layerless process that’s 25 to 100 times faster than standard 3D printing. It’s called CLIP (Continuous Liquid Interface Production). The object is not so much printed, layer by layer, but more grown from a dish of liquid.

So is 3D printing the next big thing?

There is definitely a lot of buzz about the possibilities at the moment. Some say that every home will have a 3D printer. However, the brains trust at Deloitte predict, that while 3D printing is undoubtedly a revolution, it probably won’t see one in every home. For starters, cost is a major factor. At the moment, good quality 3D printers are far too expensive to be mass-produced because there are no buyers.

You also have to take into account the potential danger when certain materials are used. For instance, metal and plastic can pose a health threat if the proper safety precautions aren’t taken. These are just a few of the reasons why 3D printers are not likely to become a household item in the very near future.

So what’s my 2 cents worth? I strongly believe that 3D printing will drive a new category of services that focuses on Safety and Health relating to operating and handling both machine and materials. Having said that, I am still looking forward to see what other things can be reinvented using this technology.